All about Roof Spandrel Panels

Table of ContentsThe Best Guide To Nhbc Spandrel Panels6 Simple Techniques For Spandrel Glass PanelLittle Known Facts About Spandrel Panel Curtain Wall.The 9-Minute Rule for Spandrel InsulationEverything about Insulated PanelsSpandrel Glass Panel Things To Know Before You Buy

Periodically, there are issues associating to having way too much uncontrolled daytime, often referred to as glow. The difficulty is to pursue the greatest visible light transmittance (VT) and the lowest solar warm gain coefficient (SHGC) while not preventing the glass from being as well reflective when viewed from both the outside and also the interior, while controlling glare.The devices need to be totally put together in a manufacturing facility as well as shipped to the website for installment on the building. The units are put on the floorings, packed in cages, making use of the tower crane and reduced right into location making use of a smaller sized crane or raise had by the glazing specialist. The mullion dimensions tend to be a little larger than a stick system because of their open area as contrasted to the tube form of a conventional stick curtain wall surface area.

Units can be constructed in a factory while the structural frame of the building is being constructed. Where stick systems require multiple actions to put up and also seal the wall, unitized wall surfaces arrive on the site totally put together allowing the floorings to be closed in quicker. Unitized systems likewise call for much less room on site for layout thus giving a benefit for city websites with space constraints.

The Only Guide for Nhbc Spandrel Panels

Solutions whose connecting legs lock also endanger the ability of the system to fit activity. Some unitized styles are sensitive to small irregularities in the spacing of surrounding modules; as an example, if the module joints are slightly out of tolerance, gaskets might not be appropriately compressed and also dampness protection may endure.

This is where area labor have to secure between adjacent units to achieve a weather condition limited wall surface. The interlacing legs of the straight mullions are the most important user interface of a unitized system.

Getting The Roof Spandrel Panels To Work

These upstanding legs have gaskets that secure versus the walls of the lower straight. A lot more robust systems will certainly offer 2 upstanding legs with gaskets on both legs.

The stack joint is the straight joint where systems from adjacent floorings meet. Positioning the stack joint at the sill of the vision glass (generally 30" over the floor) will decrease the dimension of the upright mullions. This positioning uses the back period of the mullion over the anchoring point at the piece to combat the deflection of the mullion listed below the slab.

Specify that laboratory examinations are to be conducted at an AAMA Accredited Research laboratory center. Field Mock-up: For all drape walls, supply or customized, require building and why not find out more construction and testing of an area mock-up representative of the wall/window assembly. This is ideal arranged prior to the launch of shop illustrations for window production, so that there is a chance to make layout modifications based upon the test performance of the field mock-up.

Facts About Opaque Spandrel Panels Uncovered

Field screening of curtain walls: Require the area screening of curtain wall surfaces for air seepage as well as water penetration resistance, for quality control of drape wall surface construction and setup. Need several tests with the first test on initial installments and also later examinations at approximately 35%, 70% and also at final conclusion to capture problems early and to verify continued handiwork high quality.

The information connected with this section of the BEDG on the WBDG were developed by committee and also are intended only as a way to illustrate general layout as well as building and construction concepts only. Proper use and application of the ideas illustrated in these details will vary based upon efficiency factors to consider and ecological conditions one-of-a-kind to every job as well as, consequently, do not stand for the last point of view or suggestion of the author of each area or the board participants accountable for the growth of the WBDG.

Continual steel sill blinking at the base of the drape wall protects the wall surface framework below from leak with the curtain wall. Sill flashing must have upturned end dams as well as fully sealed edges. Intermediate straight should be wept to the exterior and stop water from draining onto the head of the glazing device below.

Rumored Buzz on Nhbc Spandrel Panels

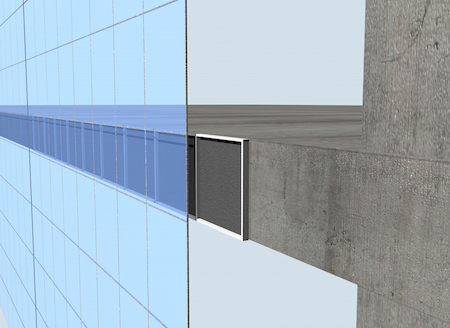

Spandrel glass adapters are made use of to decrease the deepness of the glazing pocket to suit lowered account of spandrel glass. Spandrel glass adapters need to be fully bedded in sealer as well as integrated with polishing pocket corner seals to stop water leakage from glazing pocket to building inside. Unit dimension of mating head as well as sill squeezed out profiles enables specified flooring to floor deflection at the pile joint.

Intermediate horizontals stop at the face of the upright system jamb participants at each end. Devices are hung from the leading or face of the adjacent floor or building structure using mated braces and also area applied screws with a minimum of clearance for access as well as setting up. All connections and braces located within the devices shielded or main weather seal zones are secured with appropriate sealer products throughout field setup.

Spandrel Insulation Fundamentals Explained

non-heat-treated) or fully solidified glass to stay in position until it can be replaced. Whether heat-strengthened or totally solidified, heat-treated glass products are created in a comparable style and using the same handling tools. The glass is heated up to about 650 C (1200 F), then force-cooled to develop surface area as well as edge compression.

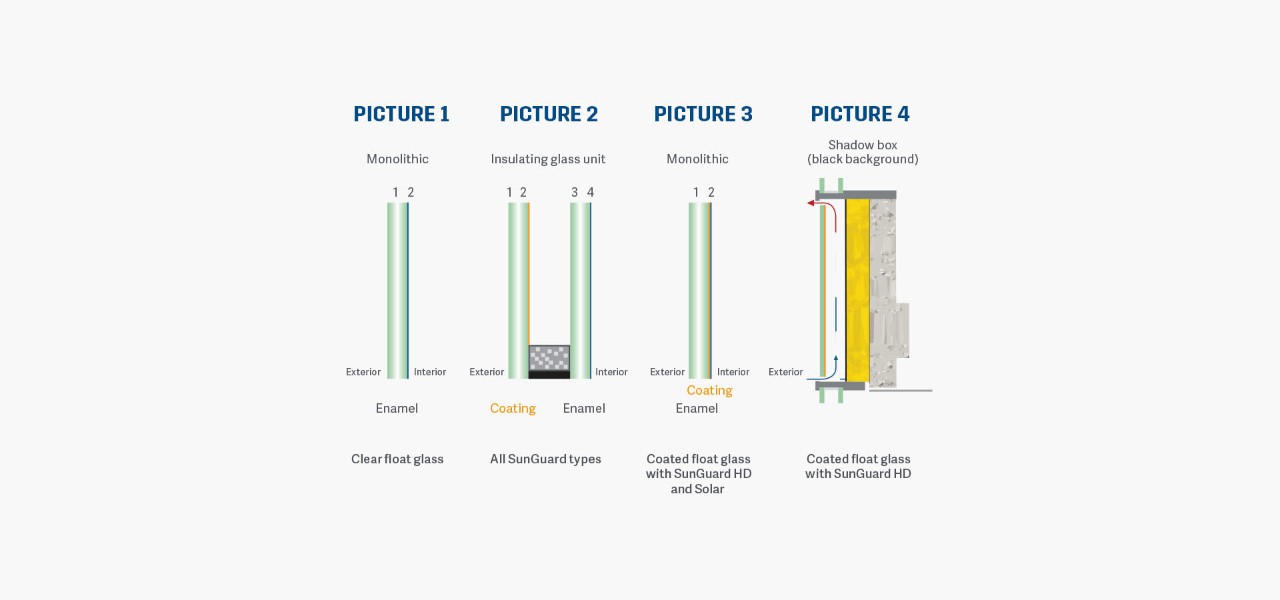

As Recommended Reading indicated in Figure 1, insulation is frequently utilized together with spandrel glass. When the insulation is to be used straight to the opacified surface area of the spandrel glass, it is very important to collaborate with a read more glass spandrel producer, along with the sticky as well as insulation suppliers, to make sure these products work with the opacifying material - spandrel glass panel.